Wear protection Say Goodbye to Endless Milling: Forming Tools Reinvented

Related Vendors

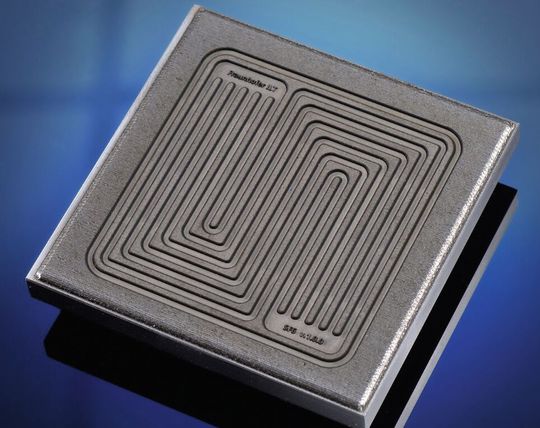

The Fraunhofer Institute for Laser Technology ILT is breaking new ground: instead of milling forming tools from solid material, it applies wear-resistant functional layers near the final contour on affordable structural steel using extreme high-speed laser cladding (EHLA).

The mass production of bipolar plates for fuel cells takes place every second. To protect the forming tools used from wear, they are milled from high-quality metal alloys. In the National Action Plan Fuel Cell Production (H2GO), the Fraunhofer Institute for Laser Technology ILT in Aachen (Germany) is taking new approaches: Instead of milling the tools from solid material, it applies wear-resistant functional layers close to the final contour on inexpensive construction steel using extreme high-speed laser material deposition (EHLA). The costs, construction time and wear of the tools are significantly reduced. Additionally, the EHLA process can be used for repairing damaged and worn tools—thus making a significant contribution to the circular economy.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/94/81/948196fc18c3feb4ec87165b218b5650/0129493778v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/da/b1/dab1af09c1f7fd43c841d8c8c60882d7/0129466462v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/26/50/2650410753c0bdf9c55989b752891a4f/0129485561v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/37/9f/379f62914fcef347331e271270e3f755/ad1i8940-4368x2456v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/05/63/05633ca5deb577945793fd0f553356b3/0129493475v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/97/3a/973acc83133c28605f855d750523142e/0129492013v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/dd/4e/dd4e6ce73e0e700dcc0f0584813ef47f/0128875162v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/17/61/1761a0165c23fe007d0a8e62d2a23121/0129467133v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/9b/e7/9be7c2ceb897aa2bf1ab4eb2198b8b96/roboter-20hand1-1240x698v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a7/34/a73475e9638e032c32288f53006abab7/newsimage417867-2665x1500v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d2/1a/d21a9b3e1333f306ffd6421e84f9e3d0/semiconductor-20image-20courtesy-20of-20gelest-3000x1688v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/f5/c6/f5c6cefa374d48138dc702821d41c7c6/greenspeed-visual-home-1500x843v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b9/47/b9470dd7a30574d74b6d95d26e4e4ee8/0129473060v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d0/bb/d0bb569e57d4b98f28bfa4b9600b245e/0129453908v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/eb/73/eb73c6f1dc08af55057cfc298c8ef72f/0128683789v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/1d/b71d25d354a0800790b525ebacd45168/a260075-large-960x540v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/8d/ff/8dffe7518cc69b90ea89c7b37f7de781/0129470810v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/35/a7/35a7cbca29eb719318324ca2e70c33c7/0129484567v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/c0/42c09f523fbe58320ac017087fb678b4/0129455974v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/72/e8/72e82e7be7eb9c7f3fe6e7bd6442b95d/0129427931v1.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/76800/76895/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/67/eb/67eba621ef6ea/logo2.png)

:quality(80)/p7i.vogel.de/wcms/f6/a1/f6a1ab3f4221c2a1ba19b47076ce20f6/0128777874v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/71/a3/71a376f07227de76312124224ec16398/0125078217v1.jpeg)