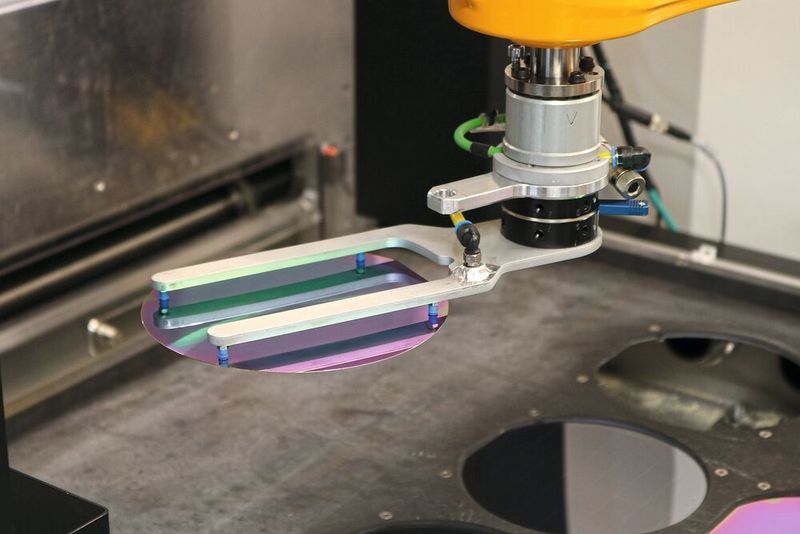

Image-Processing-Based Robotics Micrometer-Accurate Positioning of Wafers

Related Vendor

For the automated loading and unloading of a workpiece carrier with differently sized wafers prior to PECVD coating, acp systems developed an image-processing-based robotics solution for a leading manufacturer of space solar technology.

The Heilbronn-based (Germany) company Azur Space Solar Power GmbH is one of the world's leading companies in the development and production of highly efficient multi-junction solar cells for space and terrestrial concentrator systems (CPV). The solar cells are based on the latest triple- and quadruple-junction technology, where the layers are built on a germanium substrate.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/af/1e/af1ec4fca4636f521f780ba0ae009c8e/bild3-werkst-c3-bcck-20und-20werkzeug-5204x2928v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/ab/d1ab452217529e5c29a81add9aca7c22/0128871322v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/53/8853f7df2fe47a3d2c6f1879f6ac38e6/newsimage417073-1500x843v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/75/28751a17e2bcca46e53a1e7b8a84c433/schmersal-tiepner-029-6749x3796v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/fe/cdfe212a3b3206e2ff09dcdf71c11240/0129219561v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/6d/c36d161e7709095fd1de4cb9de27d927/0129133682v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/70/dc/70dc2fbc09e6958a72c63bd15e986e14/0129206156v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/fd/60fd12ddfe1fb623568736f27d1cfe61/0128606899v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/38/393873c2ed943bb715a6419d94049b63/geralt-entrepreneur-1340649-1280-1280x720v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/4e/604e2a1ce26f177c5f28c2bff94c2f7d/der-20rotor-20mit-20aktiv-20verwindbaren-20rotorbl-c3-a4ttern-20im-20windkanal-1920x1079v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/9a/a89aef1cba3843fa06a1ec1f07cf659b/adobestock-95634179--c2-a9-20crazyforanimeart-20-e2-80-93-20stock-adobe-com-4762x2678v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/fb/2bfbb9fa26274cb8f6e8979c24a3d08e/0129243542v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/25/11/25111828d56b46dc0dc3b717ac2dfcfa/0129276081v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/b7/2d/b72dfd1458e86652491018914478cb00/0129259253v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cb/76/cb76d0c686e8dbc8b0e0b6961e3849c7/0129249515v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/42/0a/420a796e6b9d9e3bf27d89d4fe425d84/0129264331v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/8f/6f8ff5bf9b81829ef22736bc790cecca/0129224894v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/3a/523ac3157ae4b4f596c7241c89127061/0129260553v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/f4/d1f4508c6b79ec2f0432b34a6fa33a98/0114966184v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/d3/fad3872cf3f110f43411f2dce9e8f23a/0129265762v1.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/76800/76895/65.jpg)

:quality(80)/p7i.vogel.de/wcms/6b/49/6b4915094aa08fbac7f8c5d54bd99414/0122489042v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/7b/a87b74052ce2cb9759d00753253b0fa7/0124565930v1.jpeg)