Machine Vision Booster for battery production

Related Vendors

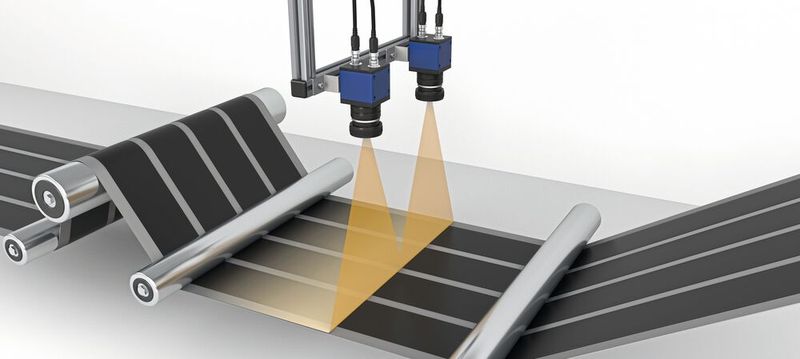

The growing importance of electric mobility requires high-performance lithium-ion batteries that must be manufactured quickly and efficiently. To optimize the corresponding workflow and maintain high quality standards, industrial image processing makes an important contribution.

Industrial image processing (Machine Vision) is a true all-round technology when it comes to the seamless automation of industrial value chains in the sense of Industry 4.0. As the "eye of production", Machine Vision is capable of continuously monitoring and optimizing all processes around manufacturing, quality assurance and logistics. In this process, image capture devices such as cameras or sensors installed at various positions collect large quantities of digital image data. Integrated Machine Vision software processes this information tightly and can identify different objects in real time based on optical features such as shape, color or texture. The technology is also ideally suited for error detection, thus playing an important role in quality assurance. The image processing is characterized by high speed, precision and particularly robust detection rates.

Sign in or register and read on

Please log in or register and read this article. To be able to read this article in full, you must be registered. Free registration gives you access to exclusive specialist information.

Already registered? Log in here

:quality(80)/p7i.vogel.de/wcms/af/1e/af1ec4fca4636f521f780ba0ae009c8e/bild3-werkst-c3-bcck-20und-20werkzeug-5204x2928v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/ab/d1ab452217529e5c29a81add9aca7c22/0128871322v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/88/53/8853f7df2fe47a3d2c6f1879f6ac38e6/newsimage417073-1500x843v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/28/75/28751a17e2bcca46e53a1e7b8a84c433/schmersal-tiepner-029-6749x3796v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/cd/fe/cdfe212a3b3206e2ff09dcdf71c11240/0129219561v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/c3/6d/c36d161e7709095fd1de4cb9de27d927/0129133682v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/70/dc/70dc2fbc09e6958a72c63bd15e986e14/0129206156v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/fd/60fd12ddfe1fb623568736f27d1cfe61/0128606899v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/39/38/393873c2ed943bb715a6419d94049b63/geralt-entrepreneur-1340649-1280-1280x720v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/60/4e/604e2a1ce26f177c5f28c2bff94c2f7d/der-20rotor-20mit-20aktiv-20verwindbaren-20rotorbl-c3-a4ttern-20im-20windkanal-1920x1079v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a8/9a/a89aef1cba3843fa06a1ec1f07cf659b/adobestock-95634179--c2-a9-20crazyforanimeart-20-e2-80-93-20stock-adobe-com-4762x2678v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/2b/fb/2bfbb9fa26274cb8f6e8979c24a3d08e/0129243542v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d2/40/d240b49c8edba464bf610f0e0b3628f0/p90629460-lowres-2250x1265v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e9/60/e960f8c34a847b11fc576c54d9d46ea6/0129325747v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/e3/8d/e38d7a9b1bcb87f6ef6546654a2ee40f/bild1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/a6/cc/a6cc273294dbe8ab9534fb4316fc8d2b/0129255976v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/6f/8f/6f8ff5bf9b81829ef22736bc790cecca/0129224894v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/52/3a/523ac3157ae4b4f596c7241c89127061/0129260553v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/d1/f4/d1f4508c6b79ec2f0432b34a6fa33a98/0114966184v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/fa/d3/fad3872cf3f110f43411f2dce9e8f23a/0129265762v1.jpeg)

:fill(fff,0)/images.vogel.de/vogelonline/companyimg/76800/76895/65.jpg)

:fill(fff,0)/p7i.vogel.de/companies/67/eb/67eba621ef6ea/logo2.png)

:quality(80)/p7i.vogel.de/wcms/af/d9/afd9722173e2a330216a8c5267ff273e/byd-blade-889x500v1v1.jpeg)

:quality(80)/p7i.vogel.de/wcms/00/90/00907b4860e11d3060011778c1244187/0125027192v1.jpeg)